Bai-link Industrial Water Monitoring Network Case

item description

In early 2021, Bai-link assisted a water purification plant located in southern China of China to establish an automated monitoring network. This water purification treatment plant needs to provide 315,000 cubic meters of water per day to the eastern islands. The maximum daily pumping capacity of the water purification plant pumping station is 295000 cubic meters. The entire water treatment plant makes optimal use of limited land resources and integrates into the natural environment through special landscape design to avoid damaging the natural landscape. In order to improve the operating efficiency of the water plant, a sophisticated supervisory control and data acquisition (SCADA) system is used to provide automated device operation, monitoring and control management.

scheme design

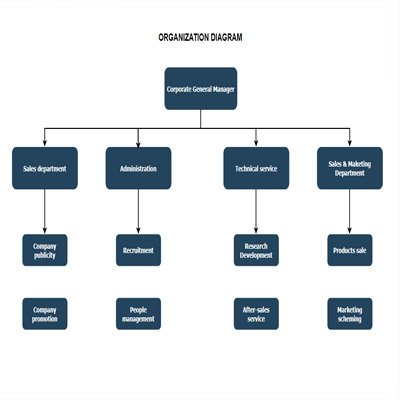

The optical fiber hybrid network system provided by Bai-link includes IES524 -4F, IES306 -2F and IES310 -2F industrial Ethernet switches, which can solve long-distance transmission over the vast area of the water purification plant area. In addition, Bai-link industrial Ethernet switches support a wide temperature range of-40 to 85℃ and can operate normally in high temperature and humid environments. Bai-link's redundant ring technology Ring (recovery time <10ms, 250 switches are running at full load) and Open-Ring (compatible with open network architecture) can quickly restore network connections when network interruptions or network failures, ensuring high-speed, stable and reliable network communication services. Therefore, Bai-link's industrial Ethernet switches can meet the requirements of network systems for instant information transmission, greatly improve work efficiency, and become the best solution for water purification plant automation for industrial control and industrial automation.

The project's optical fiber hybrid network system includes dual network architectures to achieve redundant backup of the network. Both the main network and backup network adopt the IES306 -2F simple managed Ethernet switch ring and are connected to the IES310 -2F. IES306-2F is a cost-effective redundant ring solution. IES306 -2F is an industrial-grade ultra-thin Ethernet switch with 6 interfaces. It is equipped with 4 10/100/0100Base-T (X) and 2 1000Base-FX. It is small in size and saves space. In addition, equipped with SFP modules makes the selection of transmission methods for different distances more flexible. The IES310-2F Industrial Managed Ethernet Switch is equipped with 2 Gigabit SFP slots and 8 10//100/1000Bae-T(X) ports.

Finally, the IES310-2F is connected to the IES524-4F in the control room. The IES524-4F managed redundant ring Ethernet switch is equipped with 24 10/100/1000Base-T (X) and 4 Gigabit combination ports. It can be used as an aggregation layer switch to transmit data collected by the underlying equipment to the central control room. This forms a network architecture with network redundancy and dual network redundancy.

IES306 -2F, IES310 -2F and IES524 -4F support Bai-link network management software, which can realize batch configuration, view topology through a graphical interface, and discover network faults in a timely manner. In addition, all three switches support IP-40 protection levels, ensuring that the entire network system can operate normally in any harsh environment.

Why choose Bai-link industrial-grade switches?

·Switch is small in size, easy to install, and cost-effective;

·Full Gigabit communication network that supports video and other big data transmission;

·Adopt industrial-grade design and support a wide temperature range of-40 to 85 ℃;

· MTBF of more than 60000 hours and low failure rate;